We manufacture, supply, and export a rather wide range of Metal Die Casting, Die Casting, Metal Injection Molding (MIM) and Powder metallurgy (PM) with factory both in Taiwan and China.

These products are customized as per the specific requirements of our many customers of the world over. We use the most suitable materials, manufacturing processes, in the making of these reliable, aesthetic products.

These products are customized as per the specific requirements of our many customers of the world over. We use the most suitable materials, manufacturing processes, in the making of these reliable, aesthetic products.

Metal Die Casting

Die Casting - Automotive and Industrial Device

Material:Aluminum Die Casting (ADC10/A380, ADC12/A383), Zinc Die Casting (ZA3, ZA5)

Size: Varieties, OEM Custom

Processing, category: die casting (aluminum, zinc), CNC machining, drilling, glass bead blasting, sand blasting, brushing, polishing, painting, powder coating, silk screen printing, assembly.

Coating/Surface Treatment: Anodizing (Color/Clear), Hard Anodizing, Powder Coating, Electroplating, Chrome Plating, Nickel Plating, Painting, Electro‑deposition painting (ED Coating), laser engraving.

Applications: Mechanical parts; Lighting parts; Medical equipment parts; Heat sink parts; Electrical parts; Electronic parts; Mechanical hardware parts; Pneumatic tool parts; Furniture parts; Bicycle parts; Motorcycle parts; Sports equipment parts, etc.

Package: Standard package

Shipment: sea freight, air freight, express delivery

EU RoHS (Restriction of the use of certain Hazardous Substances in electrical and electronic equipment) compliant products.

We provide high quality die casting and contract manufacturing services to global customers, specializing in low to medium volume production orders, from our factory both in Taiwan and China.

COOLMOSA has been totally vertical integration in which from mold design to aluminum or zinc alloy die-casting production.

Through mode developments, products are available in fields of medical equipment, lamp parts, auto parts, precision goods, small engines, monitors, industrial control equipment parts, network communication equipment among others.

Die Casting - Pump and Oil Filter

Material:Aluminum Die Casting (ADC10/A380, ADC12/A383), Zinc Die Casting (ZA3, ZA5)

Size: Varieties, OEM Custom

Processing, category: die casting (aluminum, zinc), CNC machining, drilling, glass bead blasting, sand blasting, brushing, polishing, painting, powder coating, silk screen printing, assembly.

Coating/Surface Treatment: Anodizing (Color/Clear), Hard Anodizing, Powder Coating, Electroplating, Chrome Plating, Nickel Plating, Painting, Electro‑deposition painting (ED Coating), laser engraving.

Applications: Various mechanical parts; electrical parts; mechanical hardware parts; pneumatic tool parts; automobile parts; sports equipment and, etc.

Package: Standard package

Shipment: sea freight, air freight, express delivery

EU RoHS (Restriction of the use of certain Hazardous Substances in electrical and electronic equipment) compliant products.

We manufacture a wide variety of custom die cast pumps and oil filters. We can meet the rapid needs of customers, with the shortest development time from prototype testing, mold development to mass production.

COOLMOSA helps our clients to quickly launch high-quality and highly competitive products, thus assisting clients to obtain the largest business opportunities in the market.

In addition to our excellent expertise and experience in die casting engineering, we are also able to vertically integrate a full range of services such as secondary machining and surface treatment, sub-assembly, full assembly and testing.

We strive to provide our clients with services that best suit their needs. Please do not hesitate to contact us at any time.

Die Casting - Electrical/Electronic Components

Material:Aluminum Die Casting (ADC10/A380, ADC12/A383), Zinc Die Casting (ZA3, ZA5)

Size: Varieties, OEM Custom

Processing, category: die casting (aluminum, zinc), CNC machining, drilling, glass bead blasting, sand blasting, brushing, polishing, painting, powder coating, silk screen printing, assembly.

Coating/Surface Treatment: Anodizing (Color/Clear), Hard Anodizing, Powder Coating, Electroplating, Chrome Plating, Nickel Plating, Painting, Electro‑deposition painting (ED Coating), laser engraving.

Applications: Various mechanical parts; electrical parts; mechanical hardware parts; pneumatic tool parts; automobile parts; sports equipment and, etc.

Package: Standard package

Shipment: sea freight, air freight, express delivery

EU RoHS (Restriction of the use of certain Hazardous Substances in electrical and electronic equipment) compliant products.

We have a variety of cold chamber die casting machines (150 tons-800 tons) for aluminum die castings and hot chamber die casting machines (30 tons-125 tons) for zinc die castings, which can provide customers with precision die casting parts in electrical and electronic products on demand.

In addition to our excellent expertise and experience in die casting engineering, COOLMOSA is also able to vertically integrate a full range of services such as secondary processing and surface treatment, sub-assembly, full assembly and testing.

We strive to provide our clients with the service that best suits their needs.

Please feel free to contact us.

Die Casting - Mounting Brackets

Material:Aluminum Die Casting (ADC10/A380, ADC12/A383), Zinc Die Casting (ZA3, ZA5)

Size: Varieties, OEM Custom

Processing, category: die casting (aluminum, zinc), CNC machining, drilling, glass bead blasting, sand blasting, brushing, polishing, painting, powder coating, silk screen printing, assembly.

Coating/Surface Treatment: Anodizing (Color/Clear), Hard Anodizing, Powder Coating, Electroplating, Chrome Plating, Nickel Plating, Painting, Electro‑deposition painting (ED Coating), laser engraving.

Applications: Various mechanical parts; electrical parts; mechanical hardware parts; pneumatic tool parts; automobile parts; sports equipment and, etc.

Package: Standard package

Shipment: sea freight, air freight, express delivery

EU RoHS (Restriction of the use of certain Hazardous Substances in electrical and electronic equipment) compliant products.

We have a variety of cold chamber die casting machines (150 tons-800 tons) for aluminum die castings and hot chamber die casting machines (30 tons-125 tons) for zinc die castings, which can provide customers with precision die casting parts in electrical and electronic products on demand.

We have the ability to provide our 30 years of experience in metal fabrication and processing to advise customers on the most cost-effective processing and manufacturing methods.

Any of our products you are interested in, please contact us.

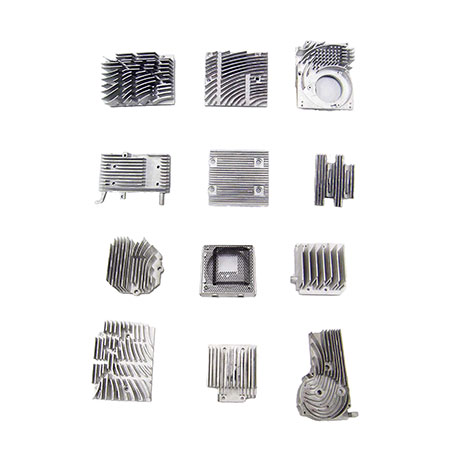

Die Casting - Heat Dissipation Unit

Material:Aluminum Die Casting (ADC10/A380, ADC12/A383)

Size: Varieties, OEM Custom

Processing, category: die casting (aluminum, zinc), CNC machining, drilling, glass bead blasting, sand blasting, brushing, polishing, painting, powder coating, silk screen printing, assembly.

Coating/Surface Treatment: Anodizing (Color/Clear), Hard Anodizing, Powder Coating, Electroplating, Chrome Plating, Nickel Plating, Painting, Electro‑deposition painting (ED Coating), laser engraving.

Applications: Various mechanical parts; electrical parts; mechanical hardware parts; pneumatic tool parts; automobile parts; sports equipment and, etc.

Package: Standard package

Shipment: sea freight, air freight, express delivery

EU RoHS (Restriction of the use of certain Hazardous Substances in electrical and electronic equipment) compliant products.

We have produced many customized aluminum heat sink die-casting parts, which are widely used in computer information industry, communication industry, and 3C electronic products.

Die cast aluminum heat sinks are cheaper than extrusion if the quantity required is large.

Aluminum heat sinks with complex shapes can be produced by die casting to reduce costs.

We have the ability to provide our 30 years of experience in metal fabrication and processing to advise customers on the most cost-effective processing and manufacturing methods.

Any of our products you are interested in, please contact us.

Die Casting - Streetlight and LED Lamp

Material:Aluminum Die Casting (ADC10/A380, ADC12/A383), Zinc Die Casting (ZA3, ZA5)

Size: Varieties, OEM Custom

Processing, category: die casting (aluminum, zinc), CNC machining, drilling, glass bead blasting, sand blasting, brushing, polishing, painting, powder coating, silk screen printing, assembly.

Coating/Surface Treatment: Anodizing (Color/Clear), Hard Anodizing, Powder Coating, Electroplating, Chrome Plating, Nickel Plating, Painting, Electro‑deposition painting (ED Coating), laser engraving.

Applications: Various mechanical parts; electrical parts; mechanical hardware parts; pneumatic tool parts; automobile parts; sports equipment and, etc.

Package: Standard package

Shipment: sea freight, air freight, express delivery

EU RoHS (Restriction of the use of certain Hazardous Substances in electrical and electronic equipment) compliant products.

We have produced many customized aluminum die-casting products for various types of LED lights, street lights, searchlights, etc.

Aluminium lamps and shades with complex shapes can be produced by die casting to reduce costs.

In addition to our excellent expertise and experience in die casting engineering, COOLMOSA is also able to vertically integrate a full range of services such as secondary processing and surface treatment, sub-assembly, full assembly and testing.

If you are interested in our products, please feel free to contact us.

Die Casting - Furniture and Sports

Material:Aluminum Die Casting (ADC10/A380, ADC12/A383), Zinc Die Casting (ZA3, ZA5)

Size: Varieties, OEM Custom

Processing, category: die casting (aluminum, zinc), CNC machining, drilling, glass bead blasting, sand blasting, brushing, polishing, painting, powder coating, silk screen printing, assembly.

Coating/Surface Treatment: Anodizing (Color/Clear), Hard Anodizing, Powder Coating, Electroplating, Electrodeposition Coating, Chrome Plating, Nickel Plating, Baking Paint, Cathodic Dip Paint (KTL), Wet Paint, Electrolysis Color coating, chemical etching, galvanizing, laser engraving.

Applications: Mechanical parts; Lighting parts; Medical equipment parts; Heat sink parts; Electrical parts; Electronic parts; Mechanical hardware parts; Pneumatic tool parts; Furniture parts; Bicycle parts; Motorcycle parts; Sports equipment parts, etc.

Package: Standard package

Shipment: sea freight, air freight, express delivery

EU RoHS (Restriction of the use of certain Hazardous Substances in electrical and electronic equipment) compliant products.

We provide high quality die casting and contract manufacturing services to global customers, specializing in low to medium volume production orders, from our factory both in Taiwan and China.

COOLMOSA is a fully vertically integrated company from mold design to aluminum or zinc alloy die casting production.

Through model development, products cover furniture and sports equipment, medical equipment, lighting accessories, auto parts, precision goods, small engines, monitors, industrial control equipment parts, network communication equipment and other fields.

In addition to our excellent expertise and experience in die casting engineering, COOLMOSA is also able to vertically integrate a full range of services such as CNC machining and surface treatment, sub-assembly, full assembly and testing.

If you are interested in our products, please feel free to contact us.

Powder metallurgy (PM), Metal Injection Molding (MIM)

Material:Carbon steel series, Copper series, Stainless steel, Alloy steel

Size: Varieties, OEM Custom

Manufacture Category: Metal powder injection molding (MIM), powder metallurgy (PM), CNC machining (milling, turning), heat treatment, vibration grinding, painting, Electro‑deposition painting (ED Coating), laser engraving and assembly.

Application: Hand tool, Electric & Pneumatic tool, Automobile, Hardware parts, 3C and other Gears and Mechanical parts

Origin, Place of shipment: Taiwan or China TBD

Package: Standard package

Shipment: sea freight, air freight, express delivery

EU RoHS (Restriction of the use of certain Hazardous Substances in electrical and electronic equipment) compliant products.

Products manufactured through metal injection molding (MIM) features similar physical, chemical, and mechanical properties to that of forged products, suitable for mass production of tiny, high precision, complex shape and metal parts with special performance requirements. The process is ideal for the production of exquisite appearance high value-added products without the need for precision finishing, and it reduces material losses.

Coolmosa has passed ISO 9001:2015 certification. We are definitely a reputable and high-quality supplier and manufacturer. We provide our clients with solutions to varying manufacturing problems.

A wide range of our MIM technology applications includes 3C electronic components, medical equipment, automobile components, bicycle gears, hand tool components, pneumatic tools, electronic tools, locks, transmission shaft accessories, etc. Please contact us if we can help in any way.

Overseas, makers are looking at

English

English Français

Français Deutsch

Deutsch Русский

Русский Português

Português Italiano

Italiano हिन्दी

हिन्दी Español

Español Nederlandse

Nederlandse العربية

العربية Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Bahasa Indonesia

Bahasa Indonesia বাঙ্গালী

বাঙ্গালী Türk

Türk 繁體中文

繁體中文