COOLMOSA TECHNOLOGY CO., LTD. is the leading Taiwan manufacturer, supplier and exporter of Metal Forging, which is manufactured using finest quality raw material and components.

Our skilled manufacture this cold forged products using advanced technology and quality material to ensure durability and high quality.

We are skilled for satisfying customers with the cost effective and quick run ability of our products. For more details of our products wanted, please contact us now!

Our skilled manufacture this cold forged products using advanced technology and quality material to ensure durability and high quality.

We are skilled for satisfying customers with the cost effective and quick run ability of our products. For more details of our products wanted, please contact us now!

Metal Forging

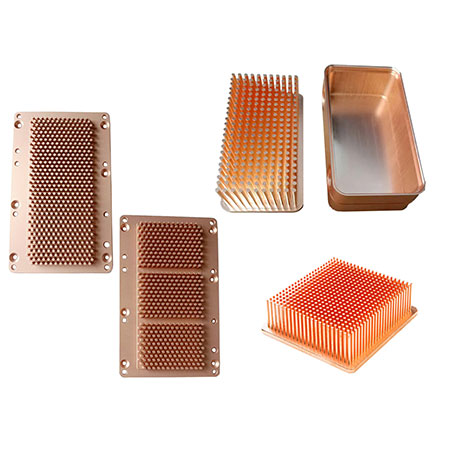

Copper Forged Heat Sink

Material: C11000 Copper.

Size: Varieties, OEM Custom

Manufacture Category: Copper Cold Forging, CNC Machining, Stamping, Anti-Oxidize

Application: Computer Cooling products, 3C Products, Industrial Products, Lighting

Origin, Place of shipment: Taiwan or China TBD

Package: Standard package

Shipment: sea freight, air freight, express delivery

EU RoHS (Restriction of the use of certain Hazardous Substances in electrical and electronic equipment) compliant products.

Today's forging process has been applied to heat sink products that require efficient heat dissipation.

Cold forged heat sinks can be used to make high-density heat dissipation pin posts or heat dissipation fins.

The heat dissipation pin post has a larger heat conduction area and heat dissipation space than the heat dissipation fins.

Under the conditions of the same material and the same size, the cold forged heat sink can improve the heat dissipation efficiency by 13~20% compared with the extrusion heat sink, and improve the heat dissipation efficiency by 5~10% compared with the skiving type heat sink.

Cold forging process is carried out at normal atmospheric temperature for forging products, high dimensional and shape accuracy, high internal density and strength, smooth surface, less machining processes and permits the mass production.

We are certificated by the ISO 9001:2015 qualification. If you interest in our products or require any further information, feel free to contact us please.

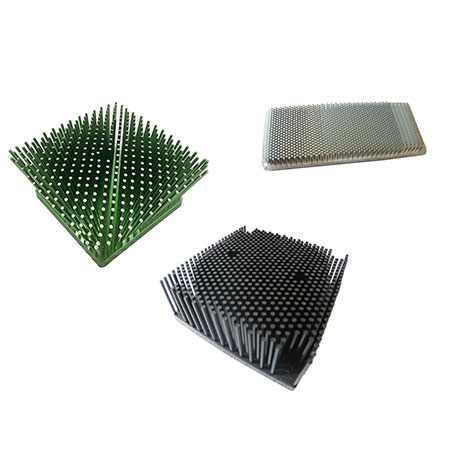

Aluminum Forged Heat Sink

Material: Aluminum AL1070, AL5052, AL6061

Size: Varieties, OEM Custom

Manufacture Category: Copper Cold Forging, CNC Machining, Stamping, Anti-Oxidize

Application: Computer Cooling products, 3C Products, Industrial Products, Lighting

Origin, Place of shipment: Taiwan or China TBD

Package: Standard package

Shipment: sea freight, air freight, express delivery

EU RoHS (Restriction of the use of certain Hazardous Substances in electrical and electronic equipment) compliant products.

The Characteristics of Cold-Forged Heat Sinks has the following characteristics.

Better thermal conductivity. Made from pure aluminum-AL1070/AL1050 by cold-forging tech. The thermal conductivity of AL1070 is 226W/m.k

Better heat dissipation structure. The base plate of a cold-forged heat sink and its fins are integrally formed, without any gap between. Heat from the base plate can be conducted into the fins without any mediators.

Larger Cooling Area. Fin thickness can be done with 0.8mm, distance between fins can be done with 1.2mm.

Diversified Fins. Fins of various shapes such as a round pin, thin fin, square columns, hexagonal columns, etc.

Large Size Heat Sinks. Dimension as large as 200mm x 250mm or even larger is achievable by cold-forging technology.

Technology Characteristics. High conductivity, high heat dispersion and high-precision, all these ensure high dimensional accuracy and stability. Thermal performance of cold-forged heat sinks is two times greater compared with the same type of die-casting parts.

Aluminum Forged LED Bulb Heat Sink

Material: Aluminum AL1070, AL5052, AL6061

Size: Varieties, OEM Custom

Manufacture Category: Copper Cold Forging, CNC Machining, Stamping, Anodizing, Assembly

Application: Computer Cooling products, 3C Products, Industrial Products, Lighting

Origin, Place of shipment: Taiwan or China TBD

Package: Standard package

Shipment: sea freight, air freight, express delivery

EU RoHS (Restriction of the use of certain Hazardous Substances in electrical and electronic equipment) compliant products.

We have produced many customized cold forging products of all kinds of LED heat dissipation lamp housing.

Aluminum LED lamps with complex shapes can be produced by cold forging process, which can reduce costs and effectively improve the heat dissipation requirements of LED lamps and prolong the life of lamps.

In addition to our excellent expertise and experience in cold forging LED lamps, COOLMOSA is also able to vertically integrate a full range of services such as secondary processing and surface treatment, sub-assembly, full assembly and testing.

We strive to provide our clients with the service that best suits their needs. Please feel free to contact us.

Forged Outdoor products

Material: Aluminum AL5052, AL6061

Size: Varieties, OEM Custom

Manufacture Category: Aluminum Forging, CNC Machining, Stamping, Riveting, vibration grinding, Polishing, Anodizing, Painting, Powder Coating, Laser Etching, Silk Screen Printing, Assembly

Application: Computer Cooling products, 3C Products, Industrial Products, Lighting

Origin, Place of shipment: Taiwan or China TBD

Package: Standard package

Shipment: sea freight, air freight, express delivery

EU RoHS (Restriction of the use of certain Hazardous Substances in electrical and electronic equipment) compliant products.

Forging process is widely adopted for the manufacturing of products varying in sizes, shapes, purposes, and mechanical structures such as outdoor products, sports, bicycle, motorcycle and medical...etc.

The advantage of the forging process is that it can process parts with complex shapes and reduce or even eliminate the need for subsequent secondary machining to reach the desired product size. Compared with the general machining process, its economic efficiency is higher.

It is well suited for mass production and significantly reduces operating costs. Compared with other manufacturing processes, it is an environmental protection process that saves materials and reduces loss.

If you are interested in forging process and forging products, please feel free to contact us.

Aluminum Forgings

Material: Aluminum AL5052, AL6061

Size: Varieties, OEM Custom

Manufacture Category: Aluminum Forging, CNC Machining, Stamping, Riveting, vibration grinding, Polishing, Anodizing, Painting, Powder Coating, Laser Etching, Silk Screen Printing, Assembly

Application: Computer Cooling products, 3C Products, Industrial Products, Lighting

Origin, Place of shipment: Taiwan or China TBD

Package: Standard package

Shipment: sea freight, air freight, express delivery

EU RoHS (Restriction of the use of certain Hazardous Substances in electrical and electronic equipment) compliant products.

Forging is one of the most important metal forming processes, especially in steel and aluminum alloy manufacturing. Forging is the process of deforming a material by forging or compression to obtain the desired shape and mechanical properties without changing its original quality and texture. Therefore, the forging process can obtain high-strength parts.

Forging generally produces little to no scrap and is therefore cheaper for medium to large production batches.

Cold forging technology does not involve cutting, and can forge high-precision products with micron-level precision in one processing.

Cold forging technology simultaneously achieves the required precision and strength of the product, making it highly durable and cost-effective.

From the development and design of forging dies, CNC machining to surface treatment, we meet the different needs of customers with vertically integrated services.

Aluminum Bicycle Forgings

Material: Aluminum AL5052, AL6061

Size: Varieties, OEM Custom

Manufacture Category: Aluminum Forging, CNC Machining, Stamping, Riveting, vibration grinding, Polishing, Anodizing, Painting, Powder Coating, Laser Etching, Silk Screen Printing, Assembly

Application: Computer Cooling products, 3C Products, Industrial Products, Lighting

Origin, Place of shipment: Taiwan or China TBD

Package: Standard package

Shipment: sea freight, air freight, express delivery

EU RoHS (Restriction of the use of certain Hazardous Substances in electrical and electronic equipment) compliant products.

Forging uses compressive forces to shape metal, transforming the original material into its final or very near final shape.

Forging technology achieves high rigidity while reducing overall weight.

Forging is the process of deforming a material by forging or compression to obtain the desired shape and mechanical properties without changing its original quality and texture. This makes forging ideal for producing strong and lightweight bicycle parts.

The characteristics of bicycles require a large number of high-strength light alloy parts, so it is particularly necessary to use forging processing methods.

From the development and design of forging dies, CNC machining to surface treatment, we meet the different needs of customers with vertically integrated services.

If you are interested in our forging products, please feel free to contact us.

our

English

English Français

Français Deutsch

Deutsch Русский

Русский Português

Português Italiano

Italiano हिन्दी

हिन्दी Español

Español Nederlandse

Nederlandse العربية

العربية Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Bahasa Indonesia

Bahasa Indonesia বাঙ্গালী

বাঙ্গালী Türk

Türk 繁體中文

繁體中文