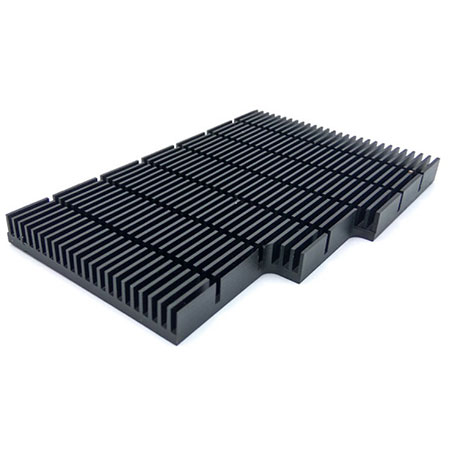

Heat Sink Enclosure

COOLMOSA TECHNOLOGY CO., LTD. specialize in the design and manufacturing of a wide range of Heat Sink Enclosure to meet the demands of the international market, the entire production process is conducted under rigid quality control measures, beside of our normal products, OEM projects are welcome.

Heat Sink Enclosure

Model - 4-3

Aluminum Extruded Heat Sink Enclosure

Nowadays, most communication electronic products and computer cases have been changed to aluminum extrusion design for heat dissipation effect and cost factors.

COOLMOSA is a fully vertically integrated company from mold design to aluminum extrusion enclosure production.

The aluminum extrusion chassis design can be decomposed into upper cover, side panel, front panel, rear panel and bottom plate. All parts can be produced by developing extrusion molds separately, and then we can vertically integrate the comprehensive services of secondary processing, such as CNC machining and surface anodizing, painting, coating, laser etching and printing, sub-assembly, full assembly and testing.

We paying great attention to maintain high quality and efficiency standards, we guarantee rapid delivery of all orders to customers.

If you are interested in any of our products, please feel free to contact us.

- Material: Aluminum Extrusion, Aluminum Plate, Aluminum Heat Sink

- Size: Varieties, OEM Custom

- Manufacture Category: AL Extrusion, CNC Machining, Stamping, Riveting, Sandblasting, Brushing, Anodizing, Painting, Powder Coating, Laser Etching, Silk Screen Printing, Assembly

- Application: Network Communication Device, Consumer Electronic Products, Electronic Information Products, Satellite Internet Equipment, Industrial Machinery

- Origin, Place of shipment: Taiwan or China TBD

- Package: Standard package

- Shipment: sea freight, air freight, express delivery

- EU RoHS (Restriction of the use of certain Hazardous Substances in electrical and electronic equipment) compliant products.

Nowadays, most communication electronic products and computer cases have been changed to aluminum extrusion design for heat dissipation effect and cost factors.

COOLMOSA is a fully vertically integrated company from mold design to aluminum extrusion enclosure production.

The aluminum extrusion chassis design can be decomposed into upper cover, side panel, front panel, rear panel and bottom plate. All parts can be produced by developing extrusion molds separately, and then we can vertically integrate the comprehensive services of secondary processing, such as CNC machining and surface anodizing, painting, coating, laser etching and printing, sub-assembly, full assembly and testing.

We paying great attention to maintain high quality and efficiency standards, we guarantee rapid delivery of all orders to customers.

If you are interested in any of our products, please feel free to contact us.

If you are interested in any of our

Heat Sink Enclosure

or would like to a customer order, please feel free to contract us, We are looking forward to forming successful business relationships with new clients around the world in the near future.Enquiry Now

Products List

IPC & MINI PC Cases

Material: Aluminum Extrusion, Aluminum Plate, Aluminum Heat Sink

Size:Varieties, OEM Custom

Manufacture Category: AL Extrusion, CNC Machining, Stamping, Riveting, Sandblasting, Brushing, Anodizing, Painting, Powder Coating, Laser Etching, Silk Screen Printing, Assembly

Application: Network Communication Device, Consumer Electronic Products, Electronic Information Products, Satellite Internet Equipment, Industrial Machinery

Origin, Place of shipment: Taiwan or China TBD

Package: Standard package

Shipment: sea freight, air freight, express delivery

EU RoHS (Restriction of the use of certain Hazardous Substances in electrical and electronic equipment) compliant products.

Aluminum profile extrusion is a processing technology that makes aluminum profiles and products by extrusion.

Most of today's industrial computers and microcomputer cases have been changed to aluminum extrusion designs for heat dissipation and save cost factors.

Aluminum extrusion is a kind of processing that through the extrusion to create aluminum shapes and products. The extrusion process is one of the best ways to uncover the true advantage of aluminum sheet.

Featuring corrosion resistance and low density, aluminum is widely used in various manufacturing processes. Aluminum extrusion is one of the most popular forms of aluminum products. The benefits of aluminum extrusion include producing high-density, high-pressure resistance, and high precision items with variable anodization. Hence, it is widely used for the production of aluminum alloy where aluminum ingots are heated and forced through extrusion molds to create products in various shapes.

If you need more information, feel free to contact us any time.

Aluminum Extruded Chassis Panels

Material: Aluminum Extrusion, Aluminum Plate, Aluminum Heat Sink

Size: Varieties, OEM Custom

Manufacture Category: AL Extrusion, CNC Machining, Stamping, Riveting, Sandblasting, Brushing, Anodizing, Painting, Powder Coating, Laser Etching, Silk Screen Printing, Assembly

Application: Network Communication Device, Consumer Electronic Products, Electronic Information Products, Satellite Internet Equipment, Industrial Machinery

Origin, Place of shipment: Taiwan or China TBD

Package: Standard package

Shipment: sea freight, air freight, express delivery

EU RoHS (Restriction of the use of certain Hazardous Substances in electrical and electronic equipment) compliant products.

Most of today's industrial computers and microcomputer enclosures, electronic information and data products, industrial products and audio amplifiers have used a large number of aluminum extruded panels to improve the texture of products and reduce manufacturing costs.

COOLMOSA is a fully vertically integrated company from mold design to aluminum extrusion enclosure production.

The aluminum extrusion chassis design can be decomposed into upper cover, side panel, panel and bottom panel. All parts can be produced separately by developing extrusion dies, and then we can vertically integrate subsequent secondary processing such as CNC machining and surface brushed, sandblasting, oxidation, screen printing, pad printing, sub-assembly, full assembly and testing services.

The products we made are very cost-effective and quality guarantee. We welcome world-while customers to establish cooperation with us.

Extruded Heat Sink

Material: Aluminum Extrusion, Aluminum Plate, Aluminum Heat Sink

Size: Varieties, OEM Custom

Manufacture Category: AL Extrusion, CNC Machining, Stamping, Riveting, Sandblasting, Brushing, Anodizing, Painting, Powder Coating, Laser Etching, Silk Screen Printing, Assembly

Application: Network Communication Device, Consumer Electronic Products, Electronic Information Products, Satellite Internet Equipment, Industrial Machinery

Origin, Place of shipment: Taiwan or China TBD

Package: Standard package

Shipment: sea freight, air freight, express delivery

EU RoHS (Restriction of the use of certain Hazardous Substances in electrical and electronic equipment) compliant products.

COOLMOSA Focusing on the field of custom heat sinks for over 30 years, specializes in innovative design and production.

Unlike traditional heat sinks, we provide a series of high performance and cost-effective heat dissipation solutions for today's and tomorrow's electronic industries.

In addition to our excellent expertise and experience in heat dissipation solutions, we are also able to vertically integrate a full range of services such as secondary machining and surface treatment, sub-assembly, full assembly and testing.

We take great pride in our production flow, integrated design, tooling development and speed to market providing excellent on time to our customer’s products and services.

If you are interested in our products, please feel free to contact us.

Skiving Heat Sink

Material: Aluminum AL1060, AL1070, AL1100, Copper C1100

Size: Varieties, OEM Custom

Manufacture Category: Skiving, CNC Machining, Riveting, Sandblasting, Brushing, Anodizing, Anti-oxidize treatment, Laser Etching, Silk Screen Printing, Assembly

Application: Network servers, 5G Communications, Military PC, IPC, Uninterruptible power system (UPS), Network Base Stations, Charging Piles, Frequency Inverters, Various Controllers, Industrial Control Equipment, Wind Power Converters, LED Lights...etc

Origin, Place of shipment: Taiwan or China TBD

Package: Standard package

Shipment: sea freight, air freight, express delivery

EU RoHS (Restriction of the use of certain Hazardous Substances in electrical and electronic equipment) compliant products.

COOLMOSA Focusing on the field of custom heat sinks for over 30 years, specializes in innovative design and production.

Skived heat sink is to use a kind of strip profile (aluminum, copper) through mechanical action to cut the materials into sheets at a certain angle and straighten them, repeated cutting to form a consistent spacing structure.

It is used to solve the heat dissipation of high-power devices under the condition of air-cooled heat dissipation, the heat dissipation efficiency can be improved by 8~15% compared with the plug-in heat sink.

The advantages of the skived heat sink process: Custom skived heat sink the fins are thin and high, the width of the heat sink can reach about 600mm, the fin tall can reach 120mm and the fin spacing is small...etc

If you are interested in our products, please feel free to contact us.

English

English Français

Français Deutsch

Deutsch Русский

Русский Português

Português Italiano

Italiano हिन्दी

हिन्दी Español

Español Nederlandse

Nederlandse العربية

العربية Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Bahasa Indonesia

Bahasa Indonesia বাঙ্গালী

বাঙ্গালী Türk

Türk 繁體中文

繁體中文