COOLMOSA TECHNOLOGY CO., LTD. is a leading manufacturer, supplier and exporter boasting over 30 years of Precision Metal Parts, with factory both in Taiwan (Taipei) and China (Dongguan City).

We are committed to manufacture the outstanding quality product through our highly skilled and dedicated employee to supply and export consistently quality products to clients.

We excel by offering customers superior service, well communication, minimizing costs and excellent flexibility in helping our clients achieve their objectives and satisfaction.

If you are interested in any styles of our products and services, please feel free to contact us.

We are committed to manufacture the outstanding quality product through our highly skilled and dedicated employee to supply and export consistently quality products to clients.

We excel by offering customers superior service, well communication, minimizing costs and excellent flexibility in helping our clients achieve their objectives and satisfaction.

If you are interested in any styles of our products and services, please feel free to contact us.

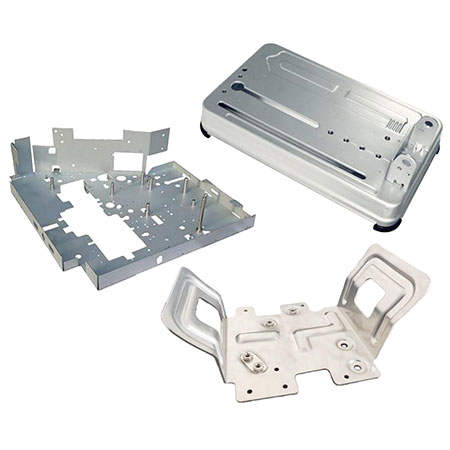

Precision Metal Parts

Rapid Prototype - Sheet Metal Fabrication

Material: Cold Rolled Steel Plate (CRS), AL5052, AL6061 Aluminum Plate, Galvanized Steel (SGCC), Galvannealed Steel (SECC), SUS304

Size: Varieties, OEM Custom

Manufacture Category: Laser Cutting, perforating, Bending, Forming, Riveting, Welding, Sandblasting, Brushing, Anodizing, Painting, Powder Coating, Laser Etching, Silk Screen Printing, Assembly.

Application: Network Communication Device, Consumer Electronic Products, Electronic Information Products, Satellite Internet Equipment

Origin, Place of shipment: Taiwan or China TBD

Package: Standard package

Shipment: sea freight, air freight, express delivery

EU RoHS (Restriction of the use of certain Hazardous Substances in electrical and electronic equipment) compliant products.

Since faster product development and technology innovation are vital to a company’s success, rapid prototyping becomes the most crucial element of new product development.

COOLMOSA offers Rapid Prototype - Sheet Metal Fabrication to help your products moving from prototyping to production fast and bringing your business to market on schedule.

According to the quantity demand of customers, we can undertake the sheet metal manufacturing and processing of various customized metal parts in a small amount and variety without making tooling.

Rapid prototyping is also great for businesses that produce low-volume needs.

We can accept 3D CAD files in STL, STEP, Solid work or IGES format and 2D drawings.

If you need any further information, please feel free to contact us.

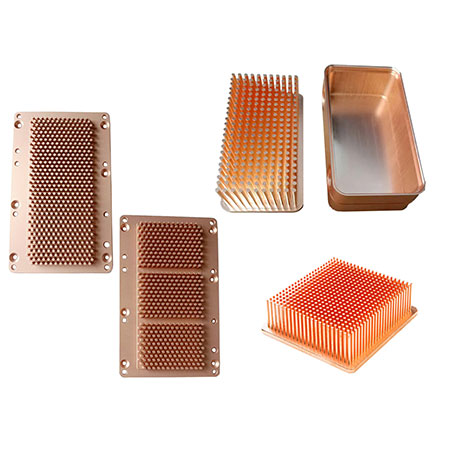

Copper Forged Heat Sink

Material: C11000 Copper.

Size: Varieties, OEM Custom

Manufacture Category: Copper Cold Forging, CNC Machining, Stamping, Anti-Oxidize

Application: Computer Cooling products, 3C Products, Industrial Products, Lighting

Origin, Place of shipment: Taiwan or China TBD

Package: Standard package

Shipment: sea freight, air freight, express delivery

EU RoHS (Restriction of the use of certain Hazardous Substances in electrical and electronic equipment) compliant products.

Today's forging process has been applied to heat sink products that require efficient heat dissipation.

Cold forged heat sinks can be used to make high-density heat dissipation pin posts or heat dissipation fins.

The heat dissipation pin post has a larger heat conduction area and heat dissipation space than the heat dissipation fins.

Under the conditions of the same material and the same size, the cold forged heat sink can improve the heat dissipation efficiency by 13~20% compared with the extrusion heat sink, and improve the heat dissipation efficiency by 5~10% compared with the skiving type heat sink.

Cold forging process is carried out at normal atmospheric temperature for forging products, high dimensional and shape accuracy, high internal density and strength, smooth surface, less machining processes and permits the mass production.

We are certificated by the ISO 9001:2015 qualification. If you interest in our products or require any further information, feel free to contact us please.

CNC Machined IPC Chassis

Material: Aluminum Extrusion, Aluminum Plate, Aluminum Heat Sink

Size: Varieties, OEM Custom

Manufacture Category: AL Extrusion, CNC Machining, Stamping, Riveting, Sandblasting, Brushing, Anodizing, Laser Etching, Silk Screen Printing, Assembly

Application: Network Communication Device, Satellite Internet Equipment, Multimedia Electrical Industrial, Audio-Visual Device

Origin, Place of shipment: Taiwan or China TBD

Package: Standard package

Shipment: sea freight, air freight, express delivery

EU RoHS (Restriction of the use of certain Hazardous Substances in electrical and electronic equipment) compliant products.

With over 30 years of experience in CNC manufacturing, Coolmosa offers a wide variety of World-class customized precision CNC machined parts, including CNC milling, CNC turning and related surface treatments and assembly.

We carry out our clients’ concept of design through sample building stage. Trial run to successfully then move to mass production.

We are capable of offering CNC machining services for material of aluminum die-casting, aluminum extrusion, metal alloy and stainless. We’re proud to have a wide spectrum of product categories and we continuously serving our clients from diversified industries such as IT industy, Medical, Network Communication, Telecom, Electronics, Optical, Automobile, Automation and etc.

We strive to provide our clients with services that best suit their needs. Please do not hesitate to contact us at any time.

Die Casting - Electrical/Electronic Components

Material:Aluminum Die Casting (ADC10/A380, ADC12/A383), Zinc Die Casting (ZA3, ZA5)

Size: Varieties, OEM Custom

Processing, category: die casting (aluminum, zinc), CNC machining, drilling, glass bead blasting, sand blasting, brushing, polishing, painting, powder coating, silk screen printing, assembly.

Coating/Surface Treatment: Anodizing (Color/Clear), Hard Anodizing, Powder Coating, Electroplating, Chrome Plating, Nickel Plating, Painting, Electro‑deposition painting (ED Coating), laser engraving.

Applications: Various mechanical parts; electrical parts; mechanical hardware parts; pneumatic tool parts; automobile parts; sports equipment and, etc.

Package: Standard package

Shipment: sea freight, air freight, express delivery

EU RoHS (Restriction of the use of certain Hazardous Substances in electrical and electronic equipment) compliant products.

We have a variety of cold chamber die casting machines (150 tons-800 tons) for aluminum die castings and hot chamber die casting machines (30 tons-125 tons) for zinc die castings, which can provide customers with precision die casting parts in electrical and electronic products on demand.

In addition to our excellent expertise and experience in die casting engineering, COOLMOSA is also able to vertically integrate a full range of services such as secondary processing and surface treatment, sub-assembly, full assembly and testing.

We strive to provide our clients with the service that best suits their needs.

Please feel free to contact us.

Our policy is to achieve customers' satisfaction both by providing them with high level

Precision Metal Parts

and services that meet or exceed their expectation.

COOLMOSA TECHNOLOGY CO., LTD. was founded in 1992 as a local stamping die and Precision Metal Parts production manufacturing company.

The main business in the early days was to develop stamping dies, manufacture computer cases and accessories, and provide various hardware products to local customers.

With the change of the globalization mode of the market, we are constantly breaking through the existing traditional factory production mode, changing to the international development direction, and providing further multi-faceted and "one-stop" services for local customers and global buyers.

In response to the development of the upgrading of the world's electronic information products, we changed to the OEM parts supply of Netcom products and heat sink products in 2001, and began to develop into a global international trade business.

Whether it is a complex part or a simple individual component, we will customize the prototype sample according to your needs.

Provide customers with practical manufacturing experience proposal based on prototype samples, and assist customers in obtaining better manufacturing cost-effectiveness in product development.

We are ISO 9001:2015 certified company that specializes in the manufacture of metal CNC turning parts, CNC machining parts, metal stamping parts, aluminum extrusions & Precision Metal Parts.

COOLMOSA TECHNOLOGY CO., LTD. currently has its own factories in Taipei Taiwan and mainland China (Dongguan). With a skilled team comprising of talented engineers and technicians.

We are experts in Custom Metal Stamping, Metal Fabrication, Metal Die Casting,CNC Metal Machining, Metal Extrusion, Metal Forging, Metal Wire Forming, and Metal Rapid Prototype.

We also provide Engineering Assembly and testing for our customers. We have more than 30 years of rich experience in this field.

We welcome world-while customers to establish cooperation with us.

If you are interested in our capabilities, products and services, please feel free to contact us or provide your design drawings and comments.

The main business in the early days was to develop stamping dies, manufacture computer cases and accessories, and provide various hardware products to local customers.

With the change of the globalization mode of the market, we are constantly breaking through the existing traditional factory production mode, changing to the international development direction, and providing further multi-faceted and "one-stop" services for local customers and global buyers.

In response to the development of the upgrading of the world's electronic information products, we changed to the OEM parts supply of Netcom products and heat sink products in 2001, and began to develop into a global international trade business.

Whether it is a complex part or a simple individual component, we will customize the prototype sample according to your needs.

Provide customers with practical manufacturing experience proposal based on prototype samples, and assist customers in obtaining better manufacturing cost-effectiveness in product development.

We are ISO 9001:2015 certified company that specializes in the manufacture of metal CNC turning parts, CNC machining parts, metal stamping parts, aluminum extrusions & Precision Metal Parts.

COOLMOSA TECHNOLOGY CO., LTD. currently has its own factories in Taipei Taiwan and mainland China (Dongguan). With a skilled team comprising of talented engineers and technicians.

We are experts in Custom Metal Stamping, Metal Fabrication, Metal Die Casting,CNC Metal Machining, Metal Extrusion, Metal Forging, Metal Wire Forming, and Metal Rapid Prototype.

We also provide Engineering Assembly and testing for our customers. We have more than 30 years of rich experience in this field.

We welcome world-while customers to establish cooperation with us.

If you are interested in our capabilities, products and services, please feel free to contact us or provide your design drawings and comments.

English

English Français

Français Deutsch

Deutsch Русский

Русский Português

Português Italiano

Italiano हिन्दी

हिन्दी Español

Español Nederlandse

Nederlandse العربية

العربية Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Bahasa Indonesia

Bahasa Indonesia বাঙ্গালী

বাঙ্গালী Türk

Türk 繁體中文

繁體中文